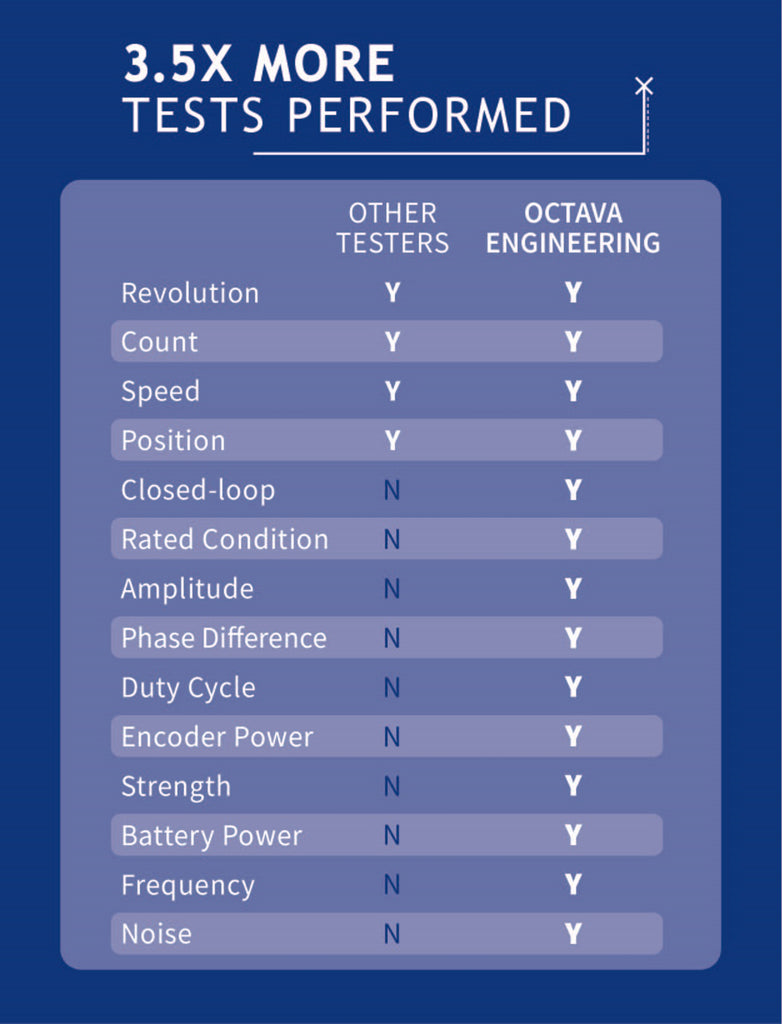

Know the received Feedback Count UP/DOWN, Alignment,

Direction CW/CCW, Reported Anomalies, and # of Critical Faults.

Rotate (FWD/REV), adjust RPM, let the motor reach operating temperature, and listen for noise and vibration.

Closed-loop system with simulated load, an absolute must if you want a quality test—no conversion to hall effect.

Auto-generated reports with your company logo reveal

whether an encoder is within spec or needs repair/replacement.

I'm really impressed, and so are the guys. The EASA St. Louis trip was worth buying the Linea X3 and RunWELL alone.

We have increased flexibility and new knowledge since our collaboration began.

Clint worked years on the repair side and knows more about servos than anyone I've ever spoken with.

Mind-blowing compared to our previous restrictions.